Introduction

EVA injection moulding machine (ethylene vinyl acetate foam injection moulding machine) is specialized in producing plastic products. It has two main parts, namely injection unit and clamping unit. Its injection unit can be fixed horizontally or vertically. Most EVA injection molding machines are designed horizontally, while vertical machines are designed to utilize gravity to mould special products. The moulding machine is mainly constituted by machinery parts, hydraulic pressure parts, electric appliances and industrial PC controlling system.

Applications

EVA injection moulding machine works with EVA mixing formula and shrunken mould cavities according to EVA linear expansion theory. During this process, materials are molded into certain products through fusion, mulling, cross linking, foaming, expansion and shrinkage. Final products by EVA injection molding machine are EVA slippers, sandals, clogs and sneaker soles and various EVA toys for children.

Advantages

1. EVA injection moulding machines function stably under Siemens industrial PC controlling. They show advantages of low malfunction rate and high efficiency. Besides, products moulded by our machines are nice in appearance, and they have low inferior-quality rate.

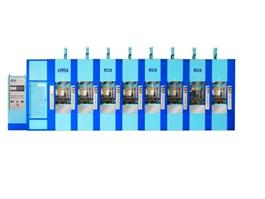

2. The injection machine can hold 4/6/8 workstations at the same time to meet different production needs.

Features

1. Orthostichous Structure

EVA injection molding machine is an automatic disc injection machine. EVA injection moulding machine applies orthostichous structure, which makes it space-saving. The orthostichous structure also makes operation easier and production cost cheaper.

2. Injection System

Controlled under PLC and PC systems, the injection moulding machine applies a potentiometer to work out accurate quantity of material needed.

3. Mould Closing System

EVA injection moulding machine works rapidly in an open-and-close system and the mould closing system is assured to proceed in a hermetic unit.

4. Controlling System

EVA injection molding machine applies human-computer interaction interface and touch screen to control production on basis of windows operation system. It realizes real-time controlling in producing procedures, including material rotate speed, injection quantity, infection time, injection temperature, sulfuring time and productivity. With PLC and PC controlling system, functions are clear to learn and operation is easy.

5. Oil Hydraulic System

EVA injection moulding machine applies proportional control valve to control oil pressure and flow.

6. Energy Saving

A metering pump is applied. During injection, oil pressure is frequently changed. Traditional injection mould machine applies single dynamo to maintain the low pressure in traditional way, so power waste is serious. But orthostichous EVA injection molding machine in Shanghai Lanteky® has three dynamos to work together to control the injection procedure. Besides, it applies water-free heating plates made from thermal insulation.

7. Others

According to Ergonomics, EVA injection moulding machine is designed in low operation height. Mould thickness adjusting is stepless, it can produce moulds in thickness of 100-260 mm.

Services

1. Pre-Sale Service

To check quality of our injection machines, customers can use the machine to mould any product according to samples they want. Customers can also watch operation of EVA injection moulding machine in our company, or we deliver products processed by the machine to customers.

2. In-Sale Service

Flimsy fittings are freely attached to EVA injection molding machine in case that old ones go wrong and need to be changed immediately. Warranty period of one year is offered to each machine, during which we can offer freely new alternatives for inartificially damaged main parts like dynamos, oil motors, oil cylinders etc, but flimsy fittings referred above excluded.

3. Other Service

Once EVA injection moulding machine is received, we will assign a technician to install the machine and train staff to use it if customer requests. During this period, customer should offer spending for the technician on visa, air plane tickets and accommodations. Our company can also introduce experts for young-established factories.

Established in 2008, Lanteky® Machinery is located in an economic development zone of the famous shoe-made city---Shanghai province. Our company is specialized in machines for producing soles of slippers, sandals and sneakers in materials of EVA, PVC, TPR, and RB, etc. To know more about our products, contact us please.