Single Color EVA Foam Injection Machine

Single Color EVA Foam Injection Machine

Two Color EVA Shoes Injection Machine

Two Color EVA Shoes Injection Machine

Two Color Rotary PVC Boot Making Machine

Two Color Rotary PVC Boot Making Machine

Single Color Rotary PVC Boot Injection Machine

Single Color Rotary PVC Boot Injection Machine

Rotary PVC Children Boot Making Machine

Rotary PVC Children Boot Making Machine

PVC Blowing Shoes Injection Machine

PVC Blowing Shoes Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

EVA Sole Injection Moulding Machine

EVA Sole Injection Moulding Machine

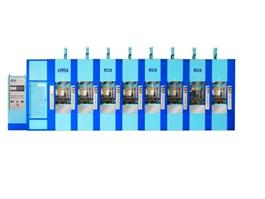

PVC Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine

|

Item |

NSK-250A-20M |

UNIT |

|

Screw rod diameter |

Ø70 |

mm |

|

Ejective capacity |

600 |

cm³/shot |

|

Mould cooling system |

water cooling |

|

|

Motor |

6P×25HP |

kW/pole |

|

Mold clamping force |

50 |

Ton |

|

Mold clamping space (max.) |

250 |

mm |

|

Size of mold available (max.) |

400×240 |

mm |

|

Mold clamping frame |

20 |

STATION |

|

Total electric consumption |

8 |

kW |

|

Machine size |

6230×3260×1900 |

mm |

|

Machine weight |

8.82 |

ton |

|

Packing dimension |

6000×2180×1800 |

mm |

|

Gross weight |

9.4 |

ton |

Tag: Automatic PU Single Density Injection Moulding Equipment | Sole Injection Machine | PU Injection Moulding Machine | Rotary Type Automatic PU Single Density Injection Moulding Machine

Tag: Plastic Air Blowing Shoes Injection Molding Equipments | Plastic Air Blowing Shoes Injection Molding Equipment | Air Blowing Plastic Shoes Injection Moulding Equipment | Air Blowing Plastic Shoes Injection Moulding Machinery