Description

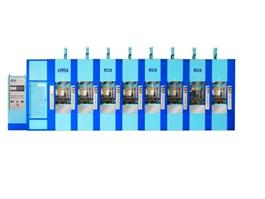

Automatic Eva foaming injection molding machine adopts unique crank and piston complex construction, the speed of opening mold, the strong close mold power. When open mold and close mold will not cause the crank point of crank system damaged. It will increases machine use life and reduce the cost of maintain and repair.

Features

1. Injection volume injection system, single mold can produce 3 to 4 paors products, raise produce capacity and products competition.

2. All computerize control system, every machine operating terms clear and easy to learn and to operate, solve the training problems.

3. Capacious memory unit can save 299 unit mold product terms information, change mold, easy and quick to set up.

Specifications of Automatic Eva Foaming Injection Molding Machine

Specification

|

Item NSK-638S

|

Mould-clamping frame

|

6 stations

|

8 stations

|

10 stations

|

Size of mould available

|

600 × 330 × (140 to 200)/mm

|

Stroke of mould clamping

|

380mm

|

380mm

|

380mm

|

Mould heating style

|

Heating

|

Heating

|

Heating

|

Screw rod diameter

|

Ø65mm

|

Ø65mm

|

Ø65mm

|

Injection capacity (Max.)

|

1320 cm³/shot

|

1320 cm³/shot

|

1320 cm³/shot

|

Injection pressure

|

180kg/cm²

|

180kg/cm²

|

180kg/cm²

|

Material injection controlling

|

Fixed volume / Pressure

|

Electric motor

|

40HPx1,10HPx1, 5HPx1

|

Electric heating capacity

|

38kW

|

49kW

|

60kW

|

Total electric consumption

|

80kW

|

91kW

|

102kW

|

Hydraulic oil volume

|

1495 liter

|

1495 liter

|

1575 liter

|

Machine size

|

5550 × 4300 × 2550 / mm

|

6650 × 4300 × 2550 / mm

|

7200 × 4300 × 2550 / mm

|

Machine weight

|

15 Tons

|

18.5 Tons

|

22.5 Tons

|

|

UK – Rigid or flexible polyurethane and polyurethane elastomer products. Component molding, reaction injection molding and extruded and co-extruded products. Components for health and fitness equipment, medical and mobility items, glazing gaskets and seals and many others. Offers injection moulding tool design, manufacture and services including single impression and multi cavity hot runner and gas injection moulding tools. Refurbished feedscrews, barrels, and components for injection moulding , blow moulding and extrusion machines.

Supplier of used injection moulding machines and other plastic machinery including extruders, ancillaries and dehumidifiers. Designers and manufacturers of bench mounted plastic injection moulding machines. Plastic injection tooling and moulding. Offer expertise on component design, tool design and moulding solutions.

Reaction injection modular molding of urethane and structural foam of parts ranging from bus bumpers to medical equipment. Injection modular molder specializing in structural foam and gas assist molding of plastics. UK – Rigid or flexible polyurethane and polyurethane elastomer products. Component molding, reaction injection molding and extruded and co-extruded products. Components for health and fitness equipment, medical and mobility items, glazing gaskets and seals and many others.

Company with diversified capabilities. Includes design and production of structural foam, injection, vacuum, and compression molds; machining of large fabrications, castings, plates, and die shoes; and finishing of machine mold bases. Manufacturing close tolerance injection modular molded parts from a variety of thermoplastic polymers. Machines from 60 to 380 tons of clamping force. Specializes in design and production of plastic and structural foam injection molds for broad range of industries. Also offers subcontracted production of plastic parts, with secondary machining and assembly capabilities.

Single Color EVA Foam Injection Machine

Single Color EVA Foam Injection Machine

Two Color EVA Shoes Injection Machine

Two Color EVA Shoes Injection Machine

Two Color Rotary PVC Boot Making Machine

Two Color Rotary PVC Boot Making Machine

Single Color Rotary PVC Boot Injection Machine

Single Color Rotary PVC Boot Injection Machine

Rotary PVC Children Boot Making Machine

Rotary PVC Children Boot Making Machine

PVC Blowing Shoes Injection Machine

PVC Blowing Shoes Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

EVA Sole Injection Moulding Machine

EVA Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine